The scarcity of resources on Earth has been debated for centuries. The impact of extracting and processing resources into the products we all use in our daily lives often comes at the expense of damaging nature and causing harm to our planet, thus impacting on our own well-being now and for future generations.

The Space Environment offers access to untapped resources and provides a unique laboratory for the discovery and formulation of new theoretical models and materials that find application in a broad range of industries.

Materials

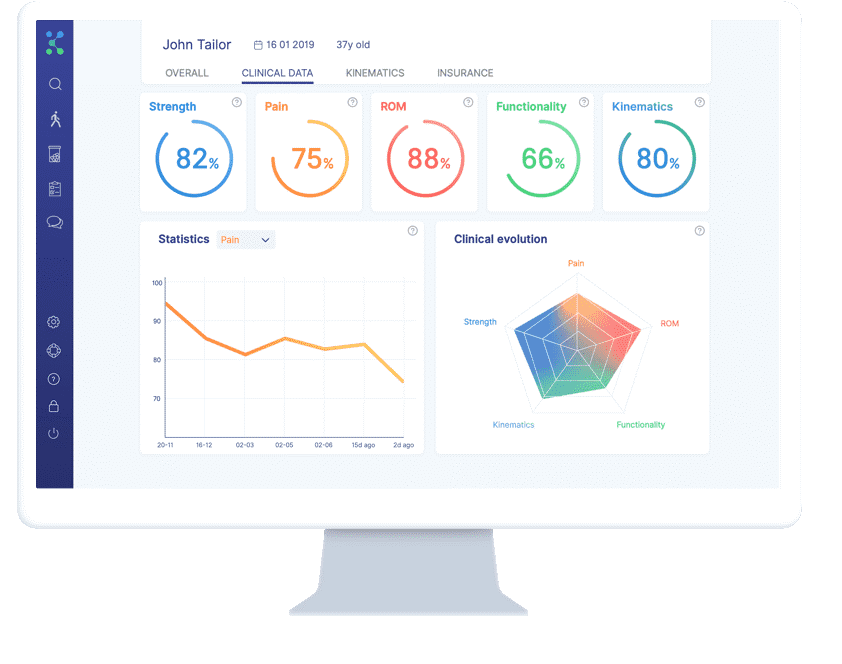

Metal production and manufacturing activities are a main driver for the economy (e.g., the steel industry in Europe alone provides over 1.8 million direct and indirect jobs). The global production of metals used for structural applications such as steel, aluminium and magnesium is expected to continue to grow at an accelerating pace. New mobility and energy concepts also require high-performance materials that can serve under extreme conditions such as very high/low temperatures, very high mechanical/dynamical loading and a very corrosive/aggressive environment. The energy transition depends on semiconductor materials, a market that is skyrocketing. New biocompatible materials are required for medical devices. Materials that demonstrate both hardness and elasticity are high in demand and even find application in the sports- and fashion industry.

An overview of materials being studies in conditions of microgravity of interest to terrestrial industries:

- Structural materials (steel, aluminium, magnesium)

- High-performance materials (nickel-, cobalt-, or iron-based superalloys)

- Functional materials (semiconductor materials such as silicon, germanium)

- Novel materials (Bulk-metallic glasses (BMG), high-entropy alloys (HEA))

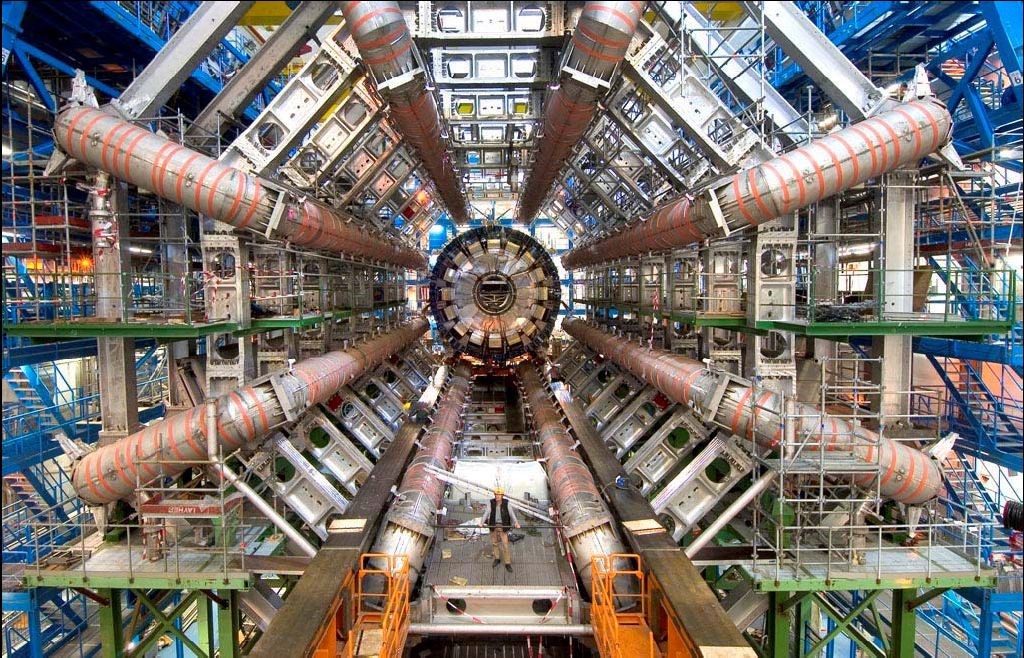

Microgravity conditions allow in particular for the gathering of experimental data on solidification physics showing an unprecedented accuracy and reliability. This benchmark data on thermophysical properties of (metallic and other) melts and on the structural evolution during the liquid-to-solid phase transition, allows for a better understanding of the solidification mechanisms and enables industrial manufacturers to better design and control their processes. Mechanical and physical properties of microstructures of material can be virtually explored and forecasted, and new routes can be discovered by using this data in simulation software. This is relevant in particular for conventional continuous and shape casting (for semi-finished and finished products), investment casting including directional and single-crystal production methods, spray forming, gas atomisation (for powder production) and other deposition techniques (for coatings), and additive manufacturing through the liquid state (3D printing).

With the rise of additive manufacturing technologies, there is also the need for the development of polymer materials that are suitable for re-use/recycling and high-strength polymers.

Mining

Advancements in science and technology are now making it possible to extract resources from astronomical bodies like Asteroids, but also from the Moon and Mars. The process of prospecting, extracting and processing these resources into products in space, requires the competence of a range of industries: materials, metallurgy, mining, energy and robotics.

Developing solutions to extract water, oxygen and metals from Regolith are expected to drive innovation and lead to the development of new technologies that could help solve problems related to resource management both on Earth and in Space. Recent studies have shown that the space resources is expected to generate market revenues from 73-170B€ between 2018-2045, supporting around 1 million full-time employee years. Technology spill-overs are expected in a range of 2.5B€ over a course of 50 years, which is considered a conservative estimation. Related technologies involve for example propellants, life support consumables, metals and materials (construction materials, Al, Fe, Ti, Si, alloys in general) as well as products of high value to Earth (platinum group metals from rich impact sites).

Access to space is not only vital to understand how we can use space resources, but also enables European Industry and Research Organisations to study and improve current methodologies related to resource management, manufacturing and mining.

Since 2019, two experiments have been flown to the ISS to study the interaction of microbes and rock in liquid medium in conditions of microgravity. The microbes act as miners on a microscopic scale, forming what is known as a Biofilm and which helps accelerate the withering of the rock. Conditions of microgravity can help to better understand how mixing regimes such as convection currents impact on the interaction between the three components. This process of Biomining is particularly relevant to the copper industry which is already making use of it today and could profit from further commercial research. See BioRock and BioAsteroid for more information.